Introduction

In my time involved in the Australian industrial electronics field, I have come across many electricians with very little instrumentation experience or training. The 4 to 20mA loop is something they would rather not touch. This article will give what I hope to be simple explanations in everyday language to assist in assessing and troubleshooting a 4 to 20mA loop.

Some History

From the beginning of the industrial revolution inventors and manufactures of machinery needed ways for the machines themselves to gauge what they were doing and automatically take corrective measures with minimal human intervention. Levers, string-lines, capillaries and later electrical cabling were all methods used through the evolution of instrumentation. Pressure to current (P to I, I to P) devices or offset-zero pneumatic systems 3-15PSIG were probably the most direct forerunner to the 4-20mA loop, and can still be found in the likes of old power stations. They can still have their place in hazardous areas where it is best not to run electrical or electronic cabling. The implementation of electronics brought about greater accuracy and stability in monitoring processes, but there was a need for a generic method to connect a wide range of sensors from different manufacturers to another wide range of controllers or displays by still further different manufacturers. Time lines are difficult to find but it seems mA current loops have been in use since the mid 1950’s. 4 to 20mA was adopted as a standard in the 1970’s and is still in wide use today, even with the availability of digital communications.

Why 4-20mA

There are a number of good reasons why the 4 to 20mA loop was adopted as a common standard.

- By starting at 4mA as an "offset-zero" there is a simple test to see if a circuit is valid. An open circuit cannot mimic 4mA, nor can a short circuit.

- The 4mA headroom allows a sensor device to be powered by the loop, and not need separate power wiring.

- Current is much more stable over long cable runs than voltage. It is not destabilised by voltage drop and is much less susceptible electrical noise.

Identifying and Testing a Loop

Probably the most confusing aspect of working with 4 to 20mA loops, is identifying the way they are wired. Sensors in a loop are most commonly “loop-powered” (2 wire loop powered), however this is not always the case. Some sensors require separate power wiring and therefore provide an “active” signal output rather than “passive”. The other distracting variation is that many reading devices will provide hidden internal connections to either the “+ve” power connection and/or the “–ve“ ground connection.

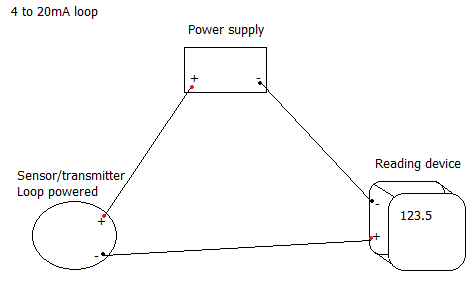

Loop-Powered Connection

- Start from “+24Vdc” on a discrete power supply, and connect directly to the “+ve” terminal on a loop-powered 4 to 20mA sensor.

- Then connect the “-ve“ terminal of the sensor to the “+ve” input terminal of the reading device.

- Then the “-ve“ terminal of the reading device back to the “-ve“ of the 24Vdc power supply.

The polarity of each of these connections is important. (see following diagram)

Separate Powered Connection

In the case of a sensor with separate connections to power, the signal output will simply be “+” on the sensor to “+” on the reading device, and “-“ on the sensor to “-“ on the reading device.

Visual Inspection

This difference needs to be noted before a visual inspection of the wiring can have any meaning as they are so different, and neither will work if wired for the other scenario. Testing with a signal calibrator (which we will cover later in the document) also needs to be set-up differently for each scenario.

Continuity Check

If it is not readily obvious where the wires are running, and you are able to isolate power from the system without disrupting a process, you can do a continuity check through each stage of the connections to verify how your circuit is connected.

Loop Voltage (loop-powered sensor)

Measuring the voltage across the “+ve” and “-ve“ of the sensor, with and without the sensor/transmitter connected, is a useful step in fault finding, however it can’t tell you anything about the signal being transmitted by the circuit. The voltage you should see in the open loop circuit needs to satisfy the requirements of the sensor. This can vary greatly, many sensors are specified as 8 to 32Vdc but you need to check the specifics of the device you are looking at. 24Vdc is commonly used in factory situations, while 12Vdc can be found in vehicle based systems or remote telemetry applications.

The voltage you will measure in the closed circuit will just be the voltage drop taken by the sensor/transmitter in the loop.

Loop Voltage (separately powered sensor)

The open loop voltage across the output of a separately powered sensor will often be between 15 and 18Vdc. As you are not looking for voltage to power the device, this test is of little use.

Loop Current

The loop current is the all-important measurement. Using a normal multi-meter or even a simulation calibrator you will need to open the loop in order to connect your meter. (You will first need to check that this will not disturb a running process before disconnecting a wire.) Fairly recent advances in the accuracy of Hall Effect devices has seen the availability of hand held meters that can measure mA current without breaking the circuit.

If you measure less than 4mA there is a problem with the circuit.

If you measure greater than 20mA again there is a problem with the circuit.

Many sensors will incorporate a function where a low reading of 3.5mA or a high reading of 22mA will have a specific meaning. As an example, a temperature transmitter may be configured to give a 22mA signal if the temperature probe connected to it has failed (causing a heating system to stop heating ie. a fail-safe situation). You would need to consult the sensor instructions to decipher this type of message and determine it is not a faulty sensor.

If you measure a reading anywhere between 4 and 20mA then it would seem your loop is working correctly. To validate the reading you will need to know the “Scaling” of the sensor.

The “Scaling” of a Loop

Simply reading the mA value of a loop is just one step in assessing the state of a 4 to 20mA loop. The entire reason for the 4 to 20mA loop was to allow many different sensing devices to communicate with many different controlling or reading devices. To understand the mA reading you are seeing, you will need to know the “Scaling” of the current-loop device. In some cases it will be stamped on a plate on the side of the device, or written on a sticker on the side or inside a device. In most cases even having the manufacturers detailed instruction manual will not be able to tell you the “Scaling” because it will have been uniquely configured by the installer.

In the example of a 4 to 20mA loop-powered temperature transmitter, the device could have been set up to a “Scaling” of 0 to 100 degC, or maybe -50 to +50degC, or even 0 to 1000degF. If it were a pressure transmitter it could be 0 to 30PSI, -1 to 500Bar or 0 to 300MPa. Without specific device information, there is no use trying to guess.

Calculating the “Scaled” Reading

Once you know the “Scale” values for the specific 4 to 20mA device, you can calculate what the mA reading is trying to tell you. Every 4 to 20mA device is assumed to be a linear scaled device and you need to have two (2) values to do the calculation. A low scale value (i.e. 4mA = X) and a high scale value (i.e. 20mA = Y). Unless you have both values you will be guessing. The calculation is a ratio and the way we see it expressed can simplify what to many can seem daunting.

In this example lets say our “Scaling” is 0 to 100%

100% (Y) 20mA

- 0% (X) - 4mA

------- --------

= 100 (Span) = 16 (Span)

100 / 16 (the ratio) = 6.25

Every 1mA above 4mA = 6.25%

If we read: 9mA we would calculate 9 – 4 (zero-offset) = 5 5 x 6.25 = 31.25%

If we read: 13.67mA 13.67 – 4 = 9.67 9.67 x 6.25 = 60.44%

Follow this link to a simple spreadsheet file for very quick calculations.

http://www.tcptechnology.com.au/documents/4_20mA_Scaling_Calculator.xlsx

Verify the Reading Device

Now that you can interpret the reading this 4 to 20mA device is giving, you can compare this single point reading to what the reading device is showing.

Every device reading a 4 to 20mA sensor/transmitter needs to have been configured with the low and high scale values so it can interpret the readings. Reading devices can be digital panel indicators, PID controllers, SCADA/PLC input modules, data loggers and the list goes on. Each will have its own way of setting and configuring the 4 to 20mA input scale values.

If this single point reading coincides with the display on the reading device then there are a lot of variables that have lined up to create a matching reading, however you wouldn’t call this a calibration.

If the reading does not line up then you are going to need to determine if it is the sensor or the reader at fault. A simulator/calibrator will be needed to go to the next level.

Calibration of a System

To calibrate a 4 to 20mA system you will need a device to simulate or in other words generate the 4 to 20mA signals so you can remove the suspect sensor/transmitter from the circuit and check that the reader is working and set correctly, or call in an instrumentation specialist to do this. As with most electronic devices these days there are economically priced devices which will suffice for troubleshooting, and more expensive items with higher resolution and stability to provide confident calibrations and worthy of maintaining annual 3rd party certification. These devices across the full spectrum will both read and simulate the signal, often the readings will have better resolution than your multi-meter (and it’s less likely someone will have blown the protection fuse than with your multi-meter).

It is important to understand how to set up the simulator device correctly for the different types of circuit we discussed earlier. If you are connecting the simulator in place of the sensor/transmitter in a loop-powered circuit, you must read the simulator manual and connect up to provide a “Sink” function.

Higher value instruments will usually incorporate an automated stepping function to move through specified steps of signal so you can verify them at the reading device and not need to run back and forth to change values or have a second person on site.

Testing the Sensor/Transmitter

If the steps above have not yet clarified the problem, or you have been requested to certify a system, you will need to prove that with the application of the range of environments to the sensor, the 4 to 20mA signal being produced is accurate.

If the circuit is for temperature measurement, best practise would be to use a dry-well calibrator to apply known stable temperatures to the probe and check the readings at a number of points preferably close to the extremes of the scaling. Electronic temperature probe simulators can be used but is still just another step in the process and doesn’t check the actual probe.

Pressure transmitters should be checked with pressure pumps or dead-weight testers.

Along these lines all parameters need to be manipulated against references and validated. Some will be more easily done than others and there is bound to be a specialised company able to validate more obscure parameters.

Galvanic Isolation – Ground Loop Errors

The most common cause of mysterious loop calibration errors is electromagnetic radiation (EMR) or ground loop errors. We said earlier that the 4 to 20mA loop provided high immunity to these interferences but it doesn’t provide immunity to the electronics in the loop-powered sensor/transmitter. The pointer to this problem is signal errors of around ±10% to 15% and if you can view a trend of the signal it will have sawtooth spikes. You will only ever see this if there is two or more loop powered devices sharing a power supply, and if there are variable speed drives in the building (even if they are well grounded and using shielded cabling). Higher specification loop-powered devices will list “galvanic isolation” as a feature. This ensures there is no electrical path between the probe signal and the loop transmission signal. These devices will cost a little more, however will be completely immune to any interference. At the other end of the measurement loop the reading device can at times be the source of interference. Again lower cost units will be non-isolated but not usually state this. Better specification devices will list “galvanic-isolation” between channels. Not only will this ensure stable readings, but it will also provide protection against lightning strikes particularly when outdoor sensors are involved or in remote telemetry applications.

Application Assistance – Equipment Purchase - Calibration

For personal assistance with your application, troubleshooting advice or purchase of test equipment, calibration equipment, isolated loop powered devices and more, please contact the author:

Rick Whatson TCP Technology Pty Ltd ph +61 (0)451 409 343 This email address is being protected from spambots. You need JavaScript enabled to view it.